Predictive maintenance might sound like a buzzword but I have seen it in action. I can take the credit for implementing it and rendering it useful for end users.

I spoke about predictive maintenance and how it can work across industries in a webinar.

Predicting unplanned failures can be beneficial to-

- Determine warranty cost

- Determine root cause of unplanned failures or inferior output

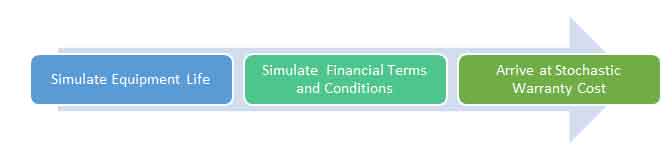

Warranty Cost

Warranty cost has been a research subject in the insurance industry for long. A manufacturer will use predictive maintenance to calculate the right warranty cost and offer the same to the customer, providing warranty, extended maintenance and service contracts. Terms and conditions of a warranty and extended warranty are designed based on insights from the warranty models.

A Typical warranty model for any industry will be similar to the one below:

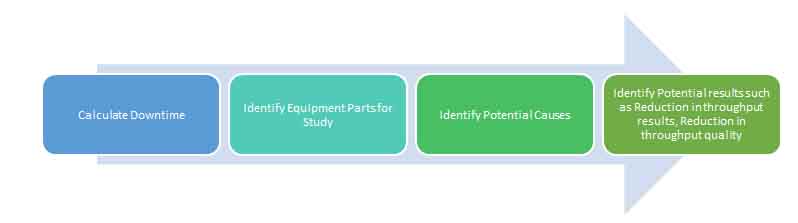

Root Cause

A typical root cause will go through following steps:

Simulate Equipment Life

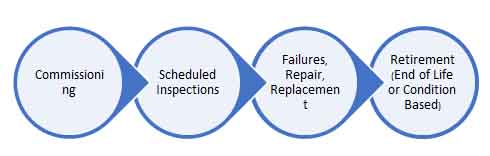

Large equipment have numerous parts, which go through many inspections, repairs, replacements, and upgrades in its lifetime. Not all parts are costly or fail often, some parts fail due to wear and tea, whereas others fail due to external factors. Of these failures, some cause downtime, and others cause sub-optimal performance. A part can be simulated through its failures, inspection, repair schedule and recording historical data of every part is theoretically feasible but one might find it hard to justify return on investment.

The life cycle of equipment parts –

An aircraft has more than 100,000 parts and the same holds true for heavy machinery. Practitioners generally follow failure mode effect analysis techniques to identify parts and failures.

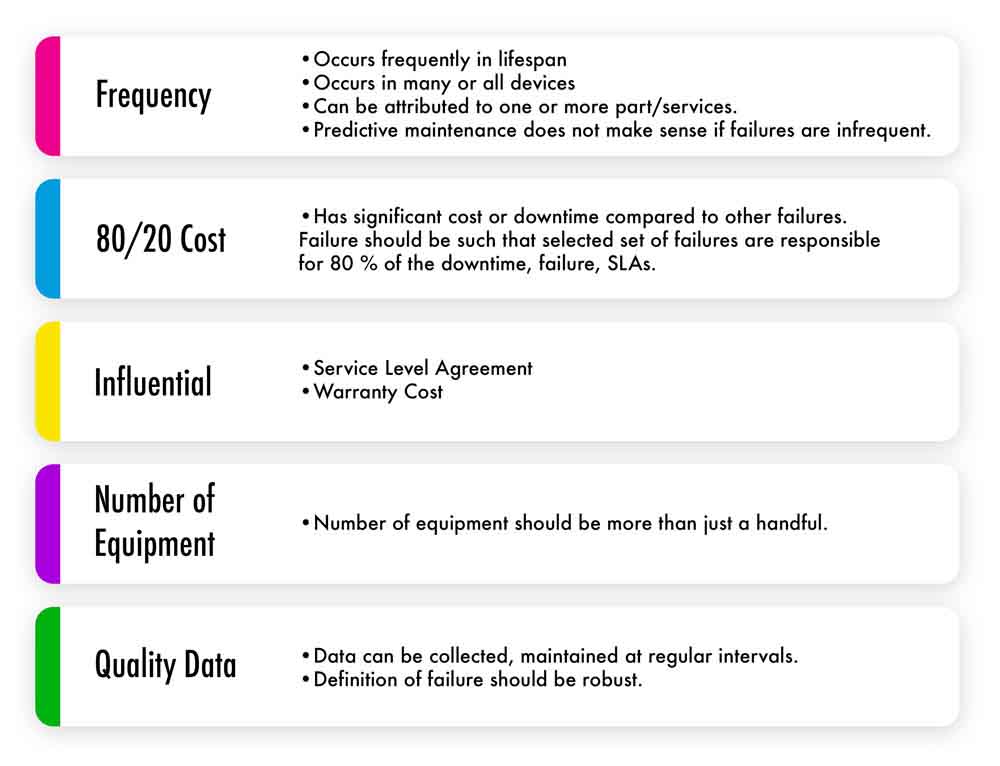

Criterion below can be chosen to decide the failure modes, parts, equipment to focus on.

These steps can be implemented when you have historical data on events and failures. Many companies still struggle to calculate system uptime, downtime statistics and reliability numbers. Obtaining downtime calculations right is an objective that can be accomplished in limited time and resources, which will be a good foundation for any type of analytics on maintenance data. If not in predictive maintenance but investment in downtime calculations will always give dividends in short and long term.

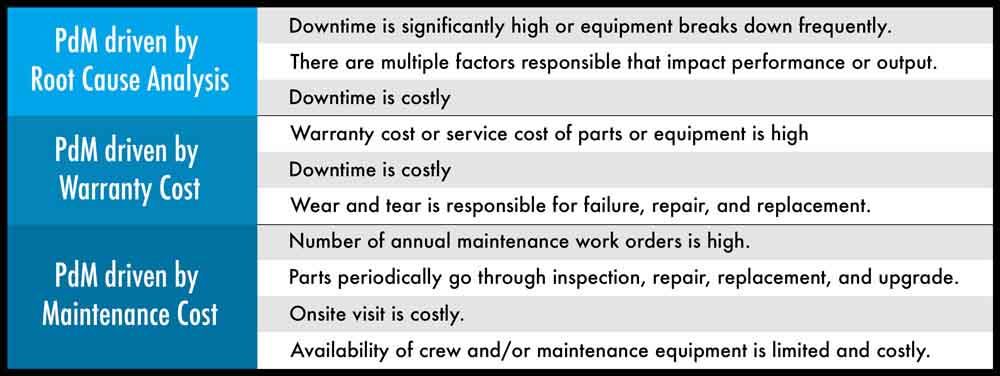

When should one go to invest in predictive maintenance?

Your business scenario should fit one of these criterions to explore predictive maintenance.

These approaches and scenarios are not mutually exclusive.

Once you determine whether your processes need predictive maintenance, the next step is to conduct a feasibility study and determine return on investment in short and long term. Looking at various predictive maintenance tools might further confuse, and using the right technology can also tip the scales in favor or not.

Experience and knowledge can go a long way when looking to step into new age technology.

A part of this post was also published here.