More than half of global companies have adopted robotic process automation (RPA) as of mid-2025, and another 43% plan to do so within the next two years. The pace is fast. In just one year, adoption jumped from 26% to 31%, a clear sign that businesses see automation as essential to staying competitive.

But behind the numbers, a different story is unfolding.

Despite high adoption, only 20 to 30% of RPA projects are considered fully successful. Around 65 to 70% deliver some value but fall short of expectations. And research shows that 30 to 50% of projects either stall, need rework, or are abandoned altogether.

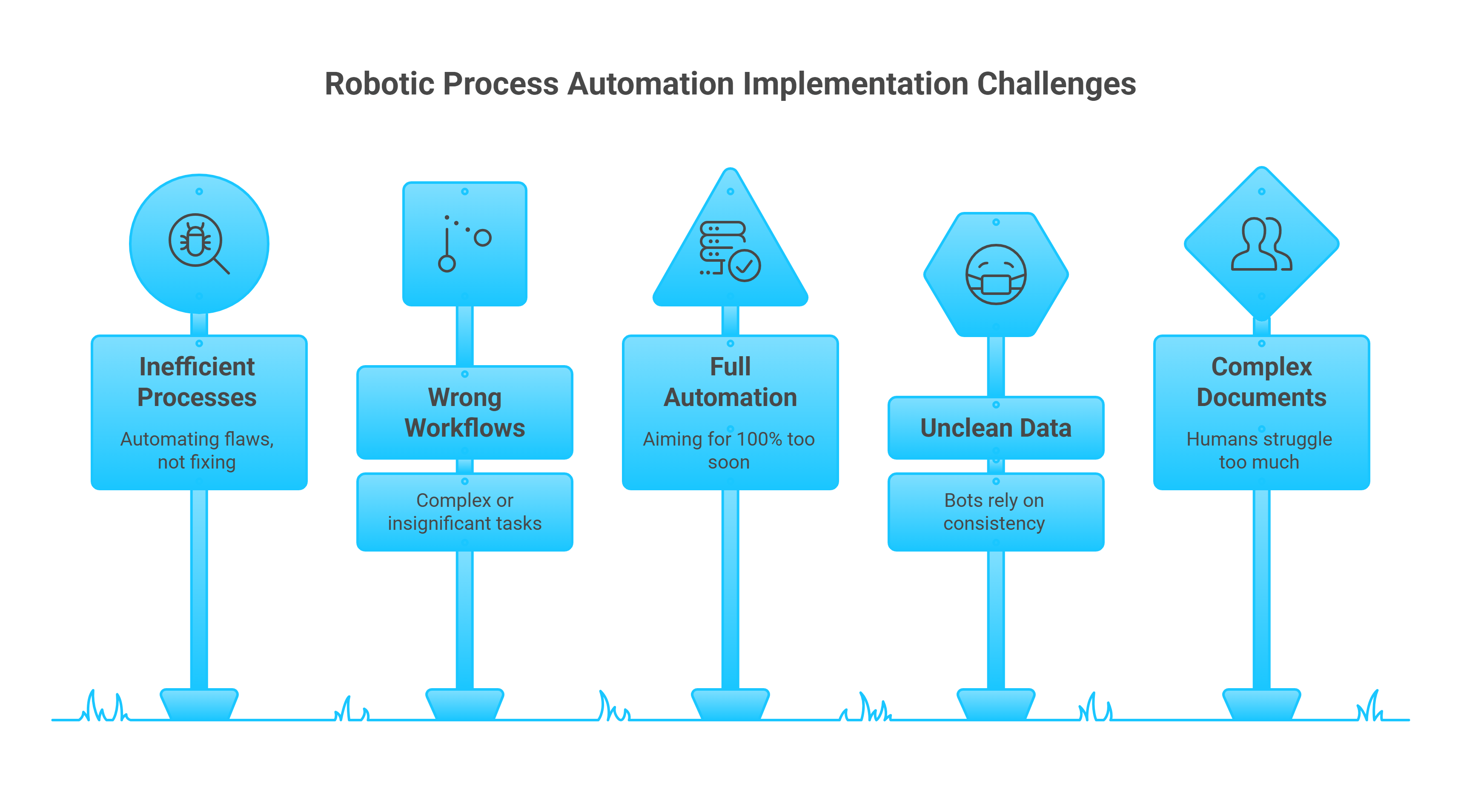

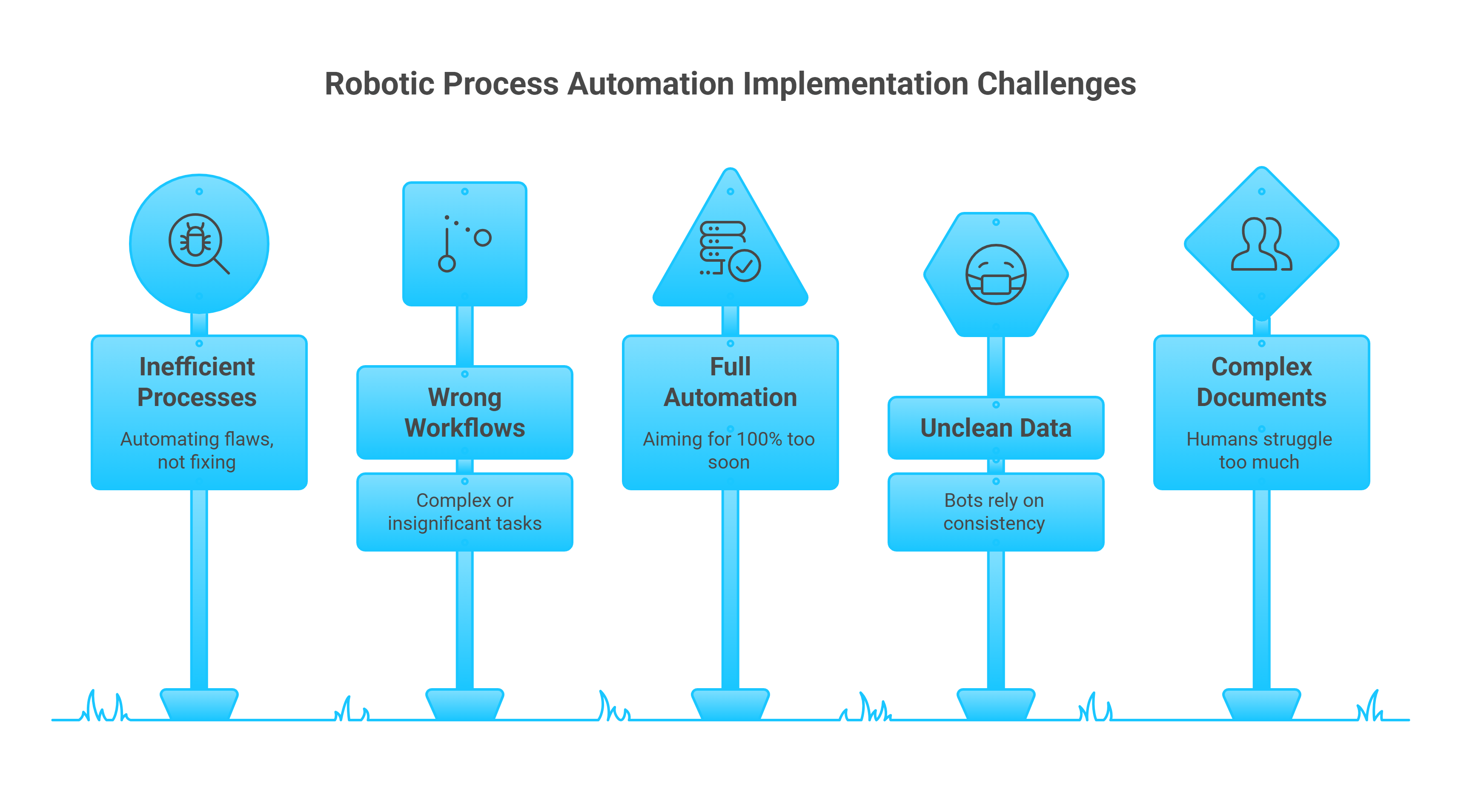

It is not because the technology does not work. It is because companies are skipping the basics.

One global courier rushed to cut costs by rolling out RPA and offshoring work at the same time. But without understanding their own systems, bots that worked in testing failed in real-life use. A major bank faced delays when internal security rules blocked developers from accessing test environments, leaving bots untested and unstable.

These are not isolated incidents. They are symptoms of a larger problem. Businesses are eager to automate, but many do not take the time to understand their own processes, systems, or limitations before doing it.

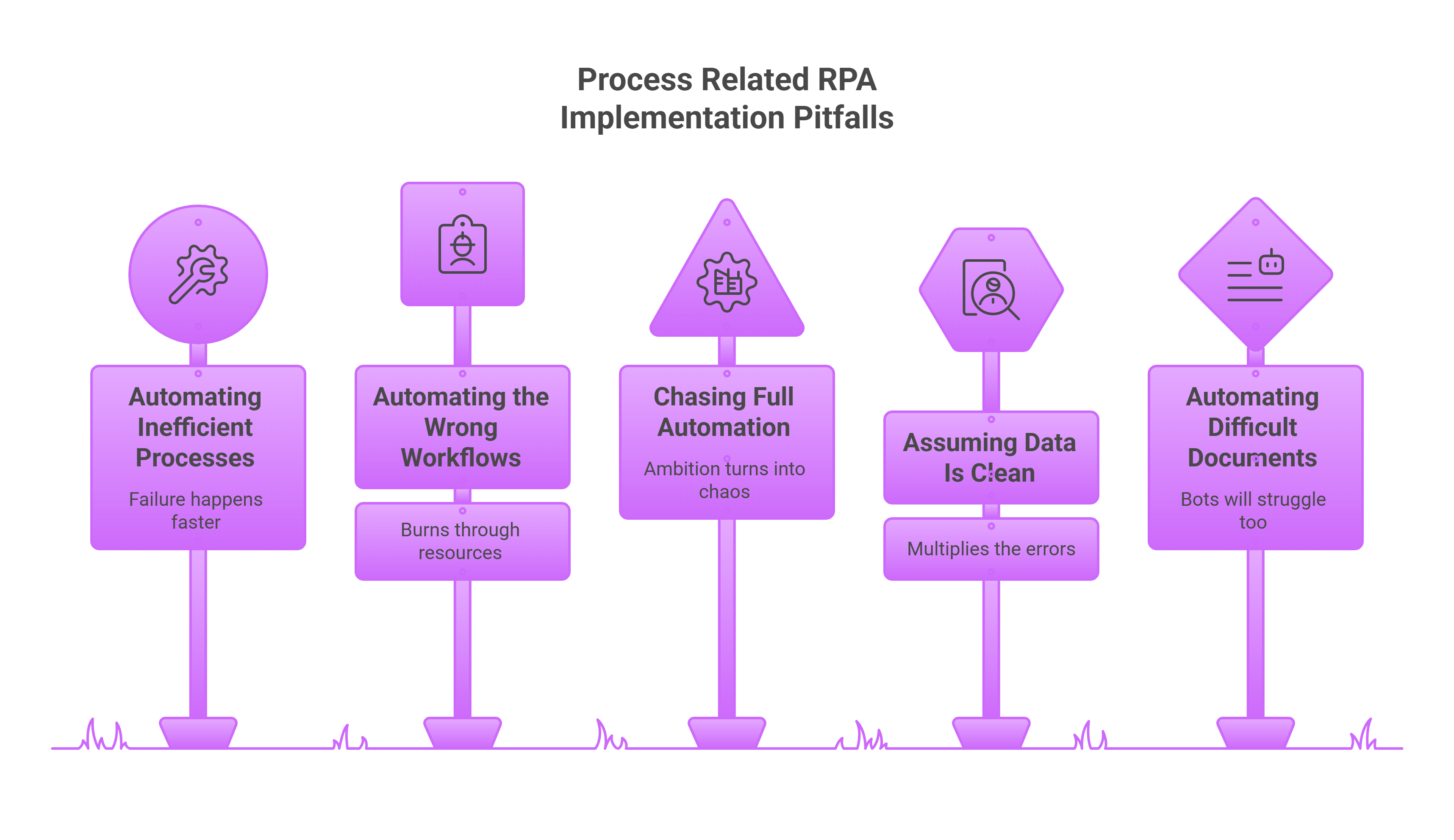

Let’s look at the most common mistakes organizations make, why they happen, and how you can avoid them to keep RPA implementation cost under control.

No one validated the data before building automation on top of it. After failure in production, the team had to go back and clean it manually, delaying the project for months and frustrating every stakeholder involved.

Bots rely on structured, consistent inputs. If the data is unreliable, automation does not just fail. It multiplies the errors system-wide.

Trying to Automate Documents That Humans Struggle With

A health insurance company attempted to automate claims processing using RPA and OCR. But claims came in all forms: scanned, handwritten, misaligned, or irregularly formatted. Bots could not extract the information reliably. The error rates were so high that human staff ended up doing more work correcting the bots than processing the forms manually.

In multiple departments, up to 66 percent of time and cost went into cleaning up automation output. Eventually, the company scaled back the automation to only the most standard documents and kept the rest manual.

OCR does not equal intelligence. If humans struggle to process something, bots will too unless backed by AI models capable of interpreting unstructured data.

Read how RPA and IDP turn unstructured data chaos into clarity with automation that scales.

Building Bots That Break with Every Minor UI Change

A global enterprise built bots that clicked on fixed screen coordinates to navigate applications. It worked until a software vendor updated the UI and moved a button. Overnight, dozens of bots stopped functioning. Transactions halted. IT teams had to scramble to manually rewrite each affected bot. Trust in the automation platform eroded.

In another case, a login screen change broke authentication workflows across multiple bots. None of them had error handling. Downtime lasted days.

Bots built with rigid logic and no resilience will always break. It is not a matter of if. It is when.

- Fix inefficiencies before automating with process mining or Lean Six Sigma

- Prioritize high-volume, rules-based processes with clear ROI

- Start small, avoid over-automation, and apply the “Rule of Five”

- Validate and clean data before building bots

- Use AI-powered OCR, NLP, and human review for unstructured inputs

- Build resilient bots with object-based selectors, APIs, and error handling

Read why RPA projects fail and discover proven fixes from 100+ real-world deployments.

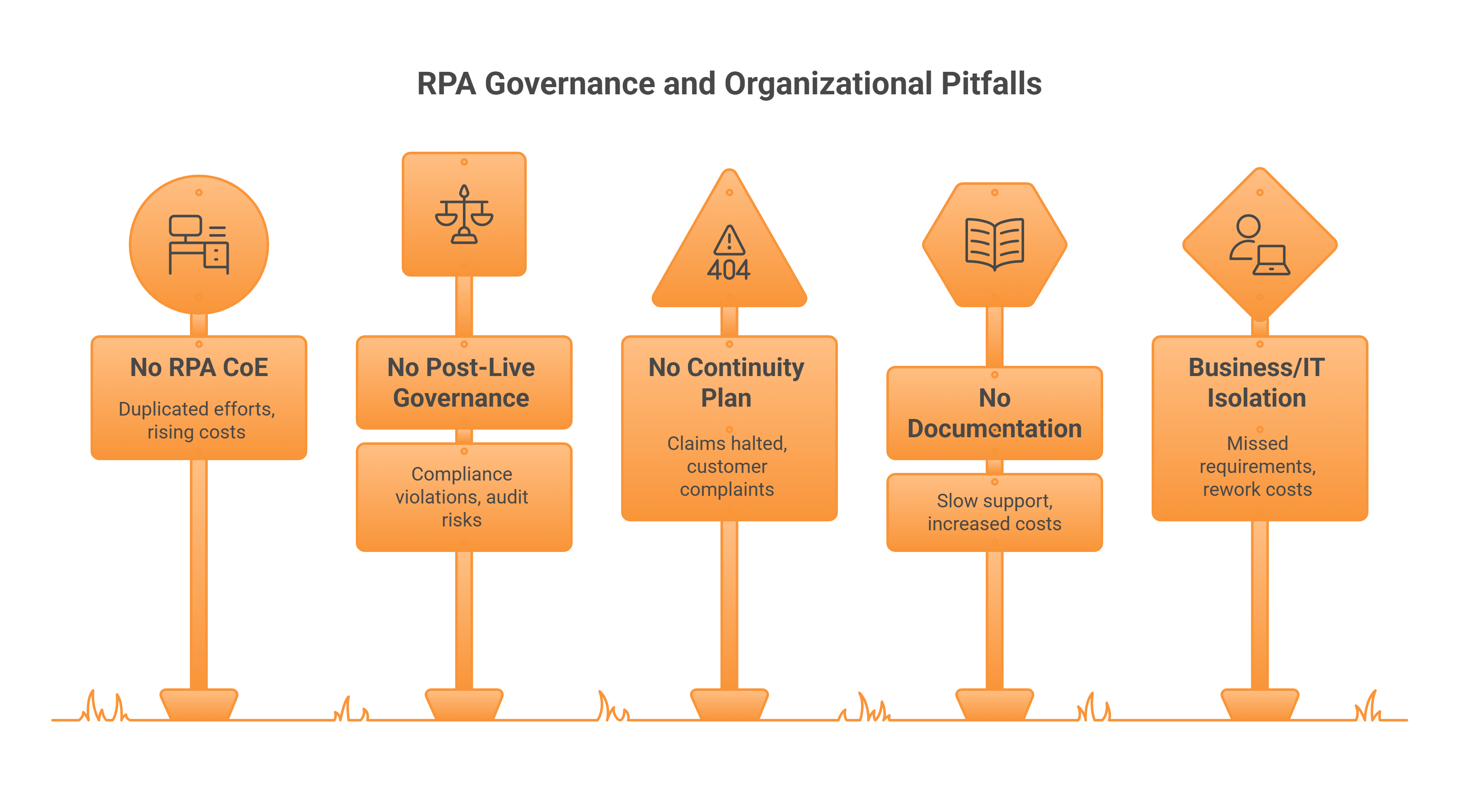

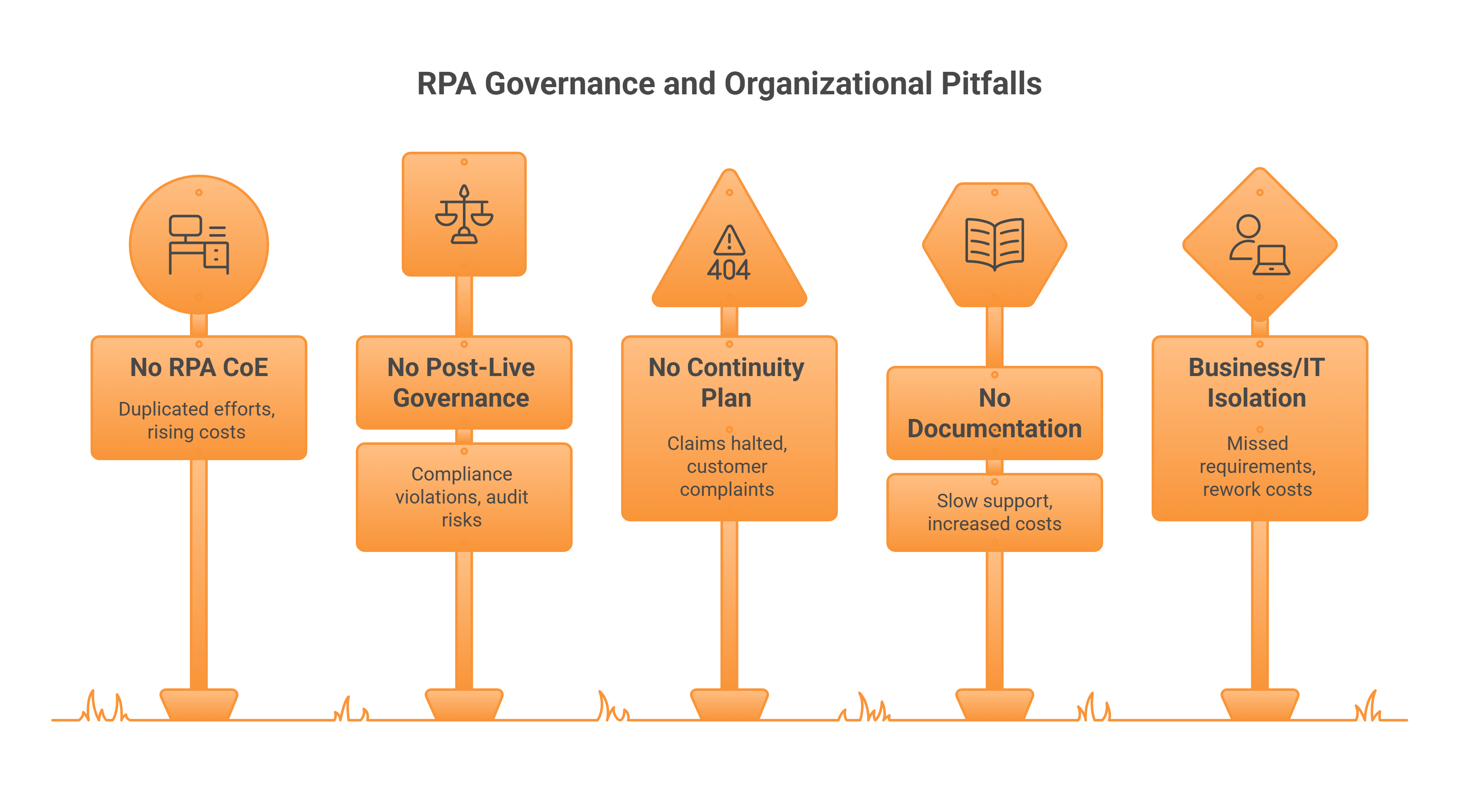

Governance & Organizational Pitfalls

Many companies implement robotic process automation without proper governance, leading to duplicated efforts, compliance risks, and stalled growth. Here are the key ones to avoid.

No RPA Center of Excellence (CoE)

A financial services firm allowed each business unit to build bots independently. The same processes were automated multiple times in different ways. The lack of consistent standards and reuse led to rising RPA implementation costs, duplicated effort, and brittle automations that were hard to maintain and scale.

This happened because there was no central RPA strategy, no oversight, and no shared platform for collaboration. Business and IT teams worked in silos, with no visibility into each other’s automation activities.

No Governance After Bots Go Live

Some firms rolled out bots with no monitoring or change control. One organization suffered compliance violations when unauthorized updates were made to bot logic. There were no audit logs, no rollback plans, and no traceability. This led to significant RPA maintenance costs and audit risks.

The failure came from treating automation as a one-time delivery rather than an ongoing operational capability. No team owned post-deployment governance, and no tools were in place to track bot health or changes.

No Business Continuity Plan for Bots

An insurance company had no fallback when a critical bot failed, halting claims processing for hours. Without mirrored bots or manual backup paths, SLA penalties and customer complaints followed. The outage drove unexpected RPA support costs and exposed gaps in automation resilience.

This happened because business continuity planning was never considered during the automation lifecycle. No fallback logic, no mirrored environments, and no manual intervention playbook.

No Documentation for Bots or Processes

In a manufacturing company, bots had been customized over time with no records of changes, inputs, or exception handling. When staff changed or bots failed, nobody knew how to fix them. Every issue required deep reverse engineering, slowing down support and increasing total cost of ownership for automation.

Documentation was skipped during the initial rollout to save time. There were no templates, no assigned owners, and no structured review process.

Business and IT Working in Isolation

A healthcare provider built a bot based solely on business team input. IT was not involved until late. The bot failed to integrate properly and had to be rebuilt. Without early coordination, automation efforts missed technical requirements, creating delivery delays and rework costs.

The issue was a lack of joint ownership. RPA delivery became a business-side initiative without platform alignment, infrastructure awareness, or shared KPIs.

Read how to avoid common pitfalls in RPA governance implementation and set your automation up for long-term success.

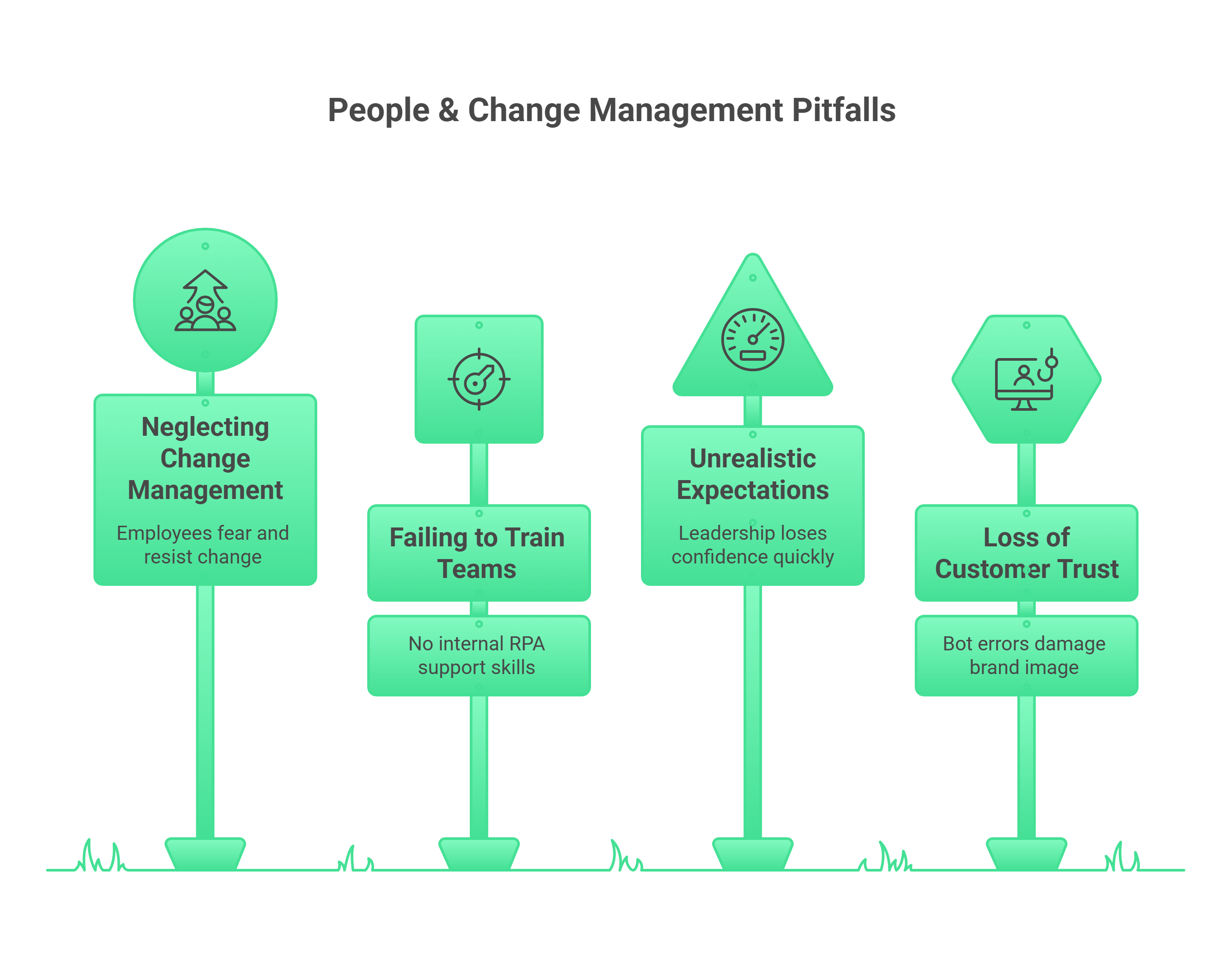

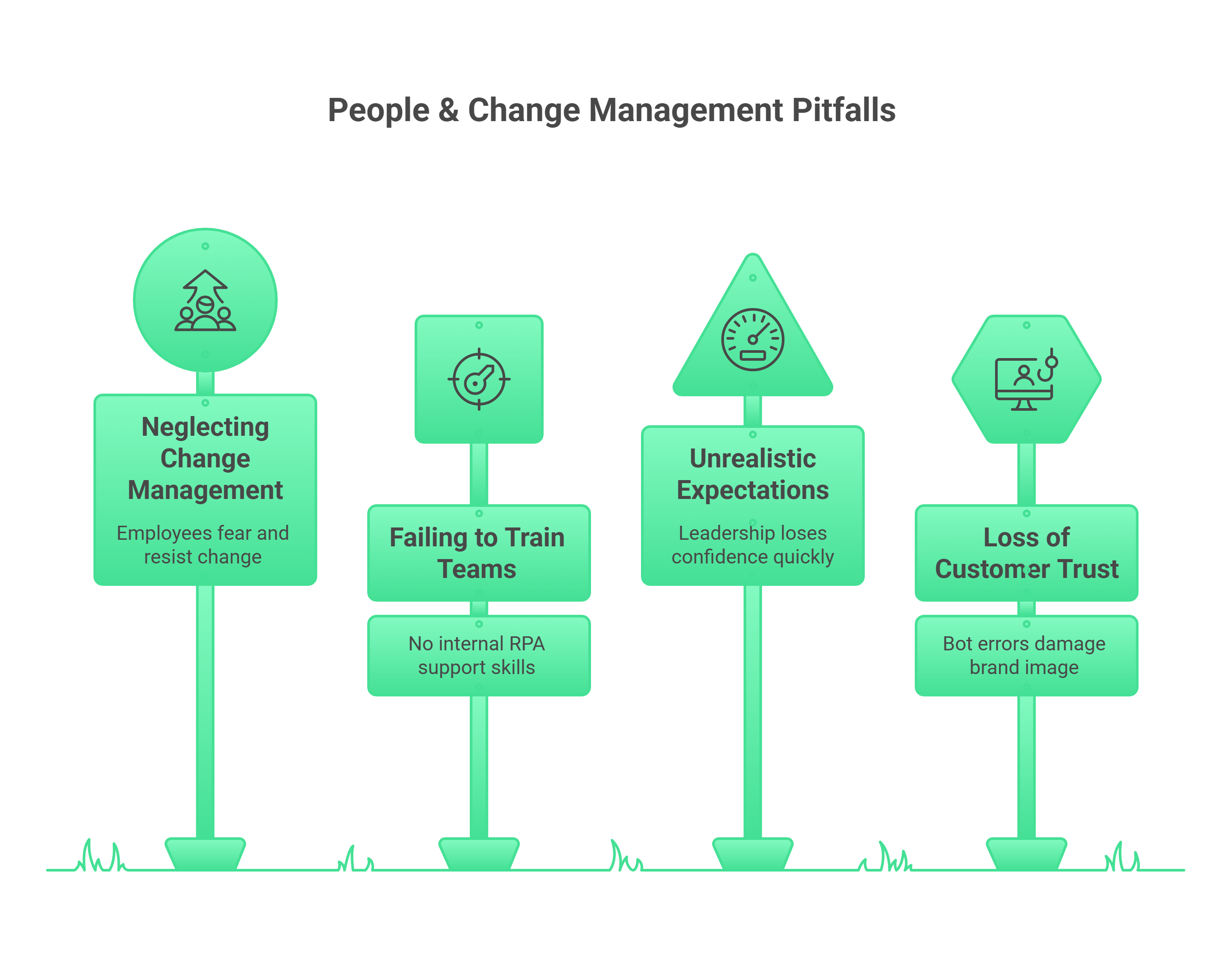

People & Change Management Pitfalls

When companies adopt robotic process automation without preparing their workforce, challenges quickly surface. Employees resist change, teams lack training, leaders set unrealistic expectations, and customer trust suffers when bots make mistakes. Here are the most common ones to address.

Neglecting Change Management

A financial services firm launched its RPA program without involving employees. No one explained the goals, benefits, or how roles would change. The silence created fear and resentment. Some employees openly resisted, while others sabotaged bots. Confusion around responsibilities led to operational delays and support issues.

This happened because leadership focused on technology delivery and ignored the need to prepare people. There was no Target Operating Model or updated KPIs to reflect how work would evolve after automation.

Failing to Train or Upskill Internal Teams

A retail company depended entirely on vendors to build and manage bots. When the contract ended, the internal team could not support or enhance the automation. Projects stalled. RPA maintenance costs rose sharply as emergency support was brought in. There was no internal knowledge or confidence to manage automation going forward.

This issue came from poor internal investment and no plan for capability building. The organization prioritized short-term delivery over long-term sustainability.

Unrealistic ROI and Time Expectations

A healthcare provider promised stakeholders rapid cost savings from RPA, without fully analyzing the complexity of their processes. Timelines slipped, bots failed, and expectations were missed. Leadership lost confidence, and the entire automation program was scaled back.

The mistake came from overpromising to secure approval and funding, without grounding estimates in validated data or pilot testing.

Loss of Customer Trust Due to Bot Errors

A telecom company automated parts of its billing system without thorough testing. One bot miscalculated and sent incorrect invoices to thousands of customers. The backlash led to brand damage, loss of customer trust, and increased churn—far outweighing any automation savings.

The cause was lack of quality control, no real-time error monitoring, and no human oversight for a high-impact customer-facing process.

- Launch a structured change management plan with clear communication and employee engagement

- Redesign roles and align KPIs to reflect how work changes with automation

- Invest in internal training, certifications, and knowledge transfer to build in-house capability

- Set realistic ROI and timeline expectations based on detailed assessments and pilot projects

- Rigorously test bots with real-world scenarios and maintain human oversight for customer-facing processes

- Implement real-time monitoring, alerts, and post-launch audits to sustain trust and quality

Security & Compliance Pitfalls

When robotic process automation is deployed without proper security and compliance controls, companies face serious risks. Weak access management, hardcoded credentials, and poor monitoring can lead to data breaches, regulatory fines, and costly downtime. Here are the key ones to avoid.

Security Oversights and Excessive Access

In several companies, bots were given full admin-level access to critical systems, including those handling financial transactions and sensitive customer data. Attackers exploited these vulnerabilities by targeting exposed bot credentials to breach internal systems. When incidents occurred, there were no complete audit trails, making it hard to trace what went wrong or how.

This happened because developers hardcoded credentials into bot scripts, and security practices were not enforced. Many organizations lacked encrypted credential vaults, detailed logging, or any role-based access model for bots.

No Role-Based Access or Credential Vaults

A large financial institution experienced repeated outages when bots stopped working after password changes. Credentials had been hardcoded into scripts. Every time a password expired or changed, developers had to manually update dozens of bots. This led to delays, failed transactions, and critical process breakdowns.

This issue emerged because there was no centralized credential management system. Bot secrets were stored in plain files or scripts, making security inconsistent and hard to maintain. Manual credential handling drove up both operational risk and long-term RPA maintenance costs.

- Enforce role-based access control (RBAC) so bots only have the minimum required permissions

- Store all credentials in a secure, encrypted vault with API-based integration and automated rotation

- Eliminate hardcoded passwords from scripts and configuration files

- Apply strong encryption (AES-256 or higher) for data at rest and in transit

- Maintain tamper-proof audit logs for all bot actions and access attempts

- Conduct regular security audits, vulnerability scans, and access reviews

- Monitor bot activity continuously for unusual or unauthorized behavior

Choosing the Right RPA Vendor Matters

When it comes to RPA implementation, technology alone is never enough. The difference between costly failures and scalable success often lies in the vendor you choose. A reliable RPA partner does more than build bots, they understand your business processes, industry regulations, and compliance requirements. They bring frameworks, governance, and expertise that help you avoid the pitfalls most organizations face.

At Nalashaa, we’ve partnered with organizations across industries to deliver automation that works in the real world.

Each of these success stories shows how the right vendor can tailor RPA solutions to specific industries, compliance requirements, and business objectives — while keeping costs under control and outcomes measurable.

Choosing an RPA vendor is not just about capability. It’s about finding a partner who can guide you through process discovery, compliance alignment, implementation, and ongoing optimization.

If you’re planning your RPA journey, work with experts who understand both your technology and your business.